Processing Additive for SMC / BMC

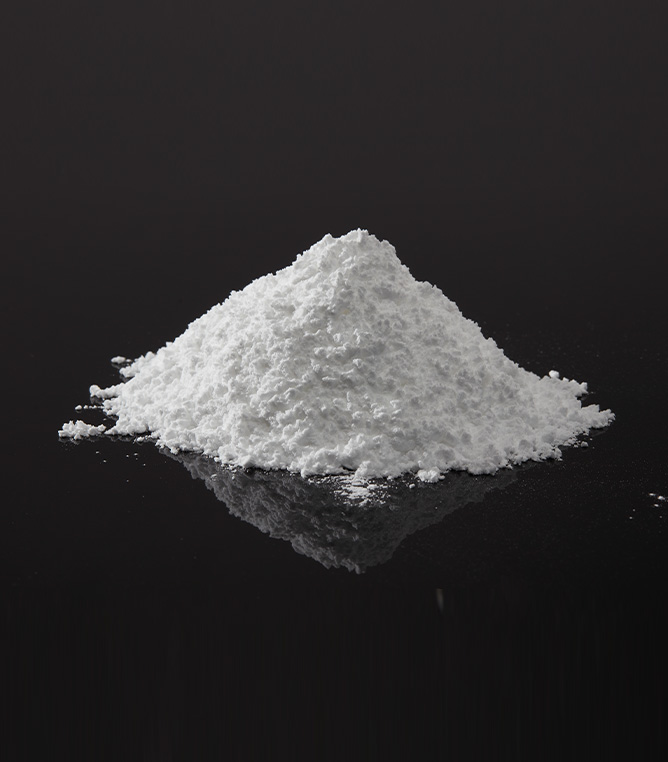

FIPOLDER™ is a high density polyethylene(HDPE) polymer in fine particle powder form.

Unlike waxes, these higher molecular weight materials exhibit high toughness.

FIPOLDER™ materials are pure polyethylene with broad regulatory compliance

and contain no residual chemicals or additives that may interfere with some

application requirements.

Unlike waxes, these higher molecular weight materials exhibit high toughness.

FIPOLDER™ materials are pure polyethylene with broad regulatory compliance

and contain no residual chemicals or additives that may interfere with some

application requirements.

Characteristics

- Ultra fine

- Impact resistance

- Narrow particle size distribution

- Abrasion resistance

- Chemical resistance

- No residual chemical solvent

- Superior hardness

The main performance

of FIPOLDER for SMC / BMC

- · Reducing shrinkage, improving coloring and flat surface, easy mold releasing

- · Advantages of PE powder compared to other low shrinkage additives ;

- PE powder is most effective in preventing warpage after molding.

- PE powder is most effective to give low profile & smoothness on molded end products.

- PE powder has good compatibility with other ingredients in SMC & BMC.

- PE powder is most effective to improve coloring of pigment.

* Coloring effect : PE, PS > PMMA > PVAc

FIPOLDER is in compliance with FDA 21 CFR177.1520 section 2.1 and 3.2

(for direct food contact during cooking)

(for direct food contact during cooking)

Applications

Bathroom Ceiling Panel

Bathtub

Door

Ceiling Panel

Water Tank

Artificial Marble

Products

| Grade | Description | Major Application | TDS | MSDS |

|---|---|---|---|---|

| FIPOLDER™ FHP05040 | Pure high density polyethylene in finely sized rounded powder form for SMC / BMC | Additive for SMC / BMC | 160426_FIPOLDER_FHP05040_Powder_TDS_TWOHChem.pdf |

231211_FIPOLDER_FHP05040_Powder_GHSMSDS_TWOHChem.pdf |