PE Coated Steel Pipe

NOVA™ for extrusion application

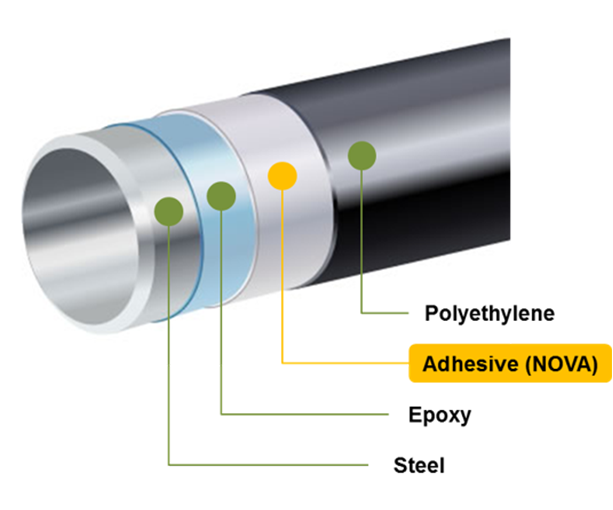

The thermoplastic adhesive resin applied to the tie layer of the

3-layer PE coating pipe. First, pre-heated steel pipe coated by epoxy resin(FBE: Fusion Bonded Epoxy). Second, NOVA™ bonds to the fusion-bonded epoxy basecoat and serves as a high-performance bonding layer for the extruded polyethylene(PE) topcoat layer. The 3-layer PE coating technology mostly preferred globally as a corrosion protection option for oil and gas pipe and water pipe projects. When used as a tie-layer with compatible FBE basecoats and PE topcoats in 3-layer coating systems, NOVA™ provides superior adhesion performance in demanding end-use applications.

The thermoplastic adhesive resin applied to the tie layer of the

3-layer PE coating pipe. First, pre-heated steel pipe coated by epoxy resin(FBE: Fusion Bonded Epoxy). Second, NOVA™ bonds to the fusion-bonded epoxy basecoat and serves as a high-performance bonding layer for the extruded polyethylene(PE) topcoat layer. The 3-layer PE coating technology mostly preferred globally as a corrosion protection option for oil and gas pipe and water pipe projects. When used as a tie-layer with compatible FBE basecoats and PE topcoats in 3-layer coating systems, NOVA™ provides superior adhesion performance in demanding end-use applications.

Characteristics

- Excellent corrosion resistance

- Advanced adhesion to substrates and topcoat

- Excellent long-term adhesion durability

- Very good chemical resistance

- Good impact resistance

- Maintain polyolefin properties

- Non-hazardous

Applications

Oil & Gas Pipeline (in the field)

Oil & Gas Pipeline (Refinery)

3 Layer Coating System for Oil & Gas Pipe (Under Water)

Products

| Grade | Description | Major Application | TDS | MSDS |

|---|---|---|---|---|

| NOVA™ APR2511 | Modified polyethylene adhesive resin for PE coated steel pipe in 3 layer coating system | Adhesive resin for gas & oil pipe | 200414_NOVA_APR2511_Pellet_TDS_TWOHChem.pdf |

200413_NOVA_APR2511_Pellet_SDS_TWOHChem.pdf |